C

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

C

Chooglin

Guest

C

Chooglin

Guest

trigger

Old Ironsides

Vendor

Lifetime Member

Supporting Member

Nice work chooglin! Looks wild from the rear.

Alan aka Davinci

Mr. Meme Master

Lifetime Member

I like your rear box, what brand is it and how much does it weigh?

trigger

Old Ironsides

Vendor

Lifetime Member

Supporting Member

Think he custom made it. It is nice.I like your rear box, what brand is it and how much does it weigh?

C

Chooglin

Guest

Yes I made it and it weighs about 20# , it's very lite !I like your rear box, what brand is it and how much does it weigh?

I added 1.00 spacers in the rear , so I figured I should extend my fenders (2.00")

One side is complete , one side to go !!

I used my stock skid plates for the filler piece !

View attachment 20628 View attachment 20629 View attachment 20630 View attachment 20631

What did you use to bend stock skid plate? Heat gun? and did u sue clips or screws to hold fenders?

Could you please show your tools and everything u used for this project.

Thx!

C

Chooglin

Guest

I used a jigsaw to cut the plastic , a propane torch to heat it and Honda push pins to secure it !!What did you use to bend stock skid plate? Heat gun? and did u sue clips or screws to hold fenders?

Could you please show your tools and everything u used for this project.

Thx!

I will post some more detailed pictures when I get home from work tonight !

advertisement

M

When are you gona start on the front?I will get those pics tomorrow, got to much going on tonight!

C

Chooglin

Guest

Ha ha , I am hoping @UTV-MudBusters will be taking care of the front very soon !When are you gona start on the front?

Post your pics of diy alsoI look forward to more pictures. I'm 99% sure going this way for the rear. It looks like if I make four offset brackets to mount to the rack, can avoid drilling those holes in the fenders.

Sent from my XT1585 using Tapatalk

C

Chooglin

Guest

I ordered new hood and fenders (yellow) so I will be making new brackets for the fenders so I don't have to drill the new fenders !I look forward to more pictures. I'm 99% sure going this way for the rear. It looks like if I make four offset brackets to mount to the rack, can avoid drilling those holes in the fenders.

C

Chooglin

Guest

I am not real good with tutorials , so I will do my best.

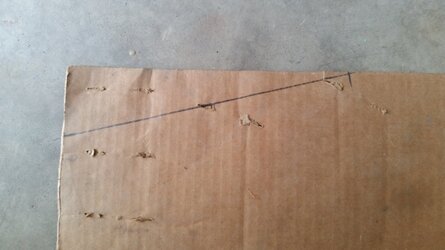

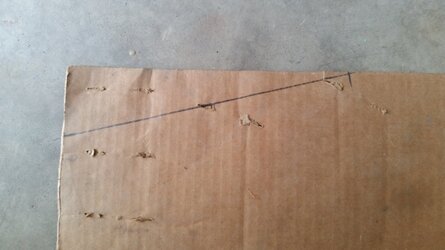

1) cut a piece of cardboard 39"x 7" to start

2)line up the cardboard with the ledge on the fender and bend one end of the cardboard around the fender ( do not try to follow the ledge when doing this). Now make a mark on the end ,where the angle would extend out to the end of the fender and mark the center of the bend.

3) now draw a line connecting the two marks you just made

4) do the same thing on the other end

5)after you get the two angles drawn , measure a width of 3 1/2" along the lines.

6) now cut the template with a utility knife

7) cut the plastic using the template.

8)heat the plastic and make the bends using the fender as a guide !

Do not get the torch to close , you want to heat it , not burn it !

9)parts should look like this !

You will have a left and a right (mirror image of each other)

10) transfer holes from fender and center piece to the filler piece and drill !

11) 4 of the holes will need to be heated and bent on a angle (the four holes closest to the seat)

12) You will need 10 adittional push pins to assemble

13)either add 4 new bracket to the wrack , or drill your fenders and use spacers for the 4 bolts

1) cut a piece of cardboard 39"x 7" to start

2)line up the cardboard with the ledge on the fender and bend one end of the cardboard around the fender ( do not try to follow the ledge when doing this). Now make a mark on the end ,where the angle would extend out to the end of the fender and mark the center of the bend.

3) now draw a line connecting the two marks you just made

4) do the same thing on the other end

5)after you get the two angles drawn , measure a width of 3 1/2" along the lines.

6) now cut the template with a utility knife

7) cut the plastic using the template.

8)heat the plastic and make the bends using the fender as a guide !

Do not get the torch to close , you want to heat it , not burn it !

9)parts should look like this !

You will have a left and a right (mirror image of each other)

10) transfer holes from fender and center piece to the filler piece and drill !

11) 4 of the holes will need to be heated and bent on a angle (the four holes closest to the seat)

12) You will need 10 adittional push pins to assemble

13)either add 4 new bracket to the wrack , or drill your fenders and use spacers for the 4 bolts

Last edited by a moderator:

Thx for the additional pics and input.

So, it looks like I can get both out of a 12" x 48" piece of HDPE. Is it 1/4" or 3/8" thick?

OK measured my bottom skid plate and got 1/4", and the part it will bolt to is 1/8". Ordering the 1/4" along with pieces for front flares. :0

C

Chooglin

Guest

advertisement

Similar threads

K

- Replies

- 5

- Views

- 700

- Replies

- 4

- Views

- 552

- Replies

- 4

- Views

- 293

R

- Replies

- 27

- Views

- 2K

R